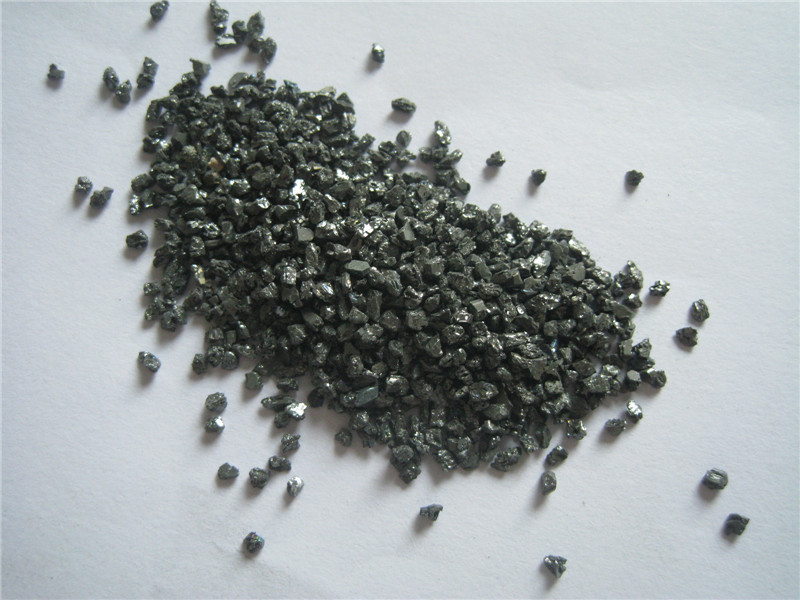

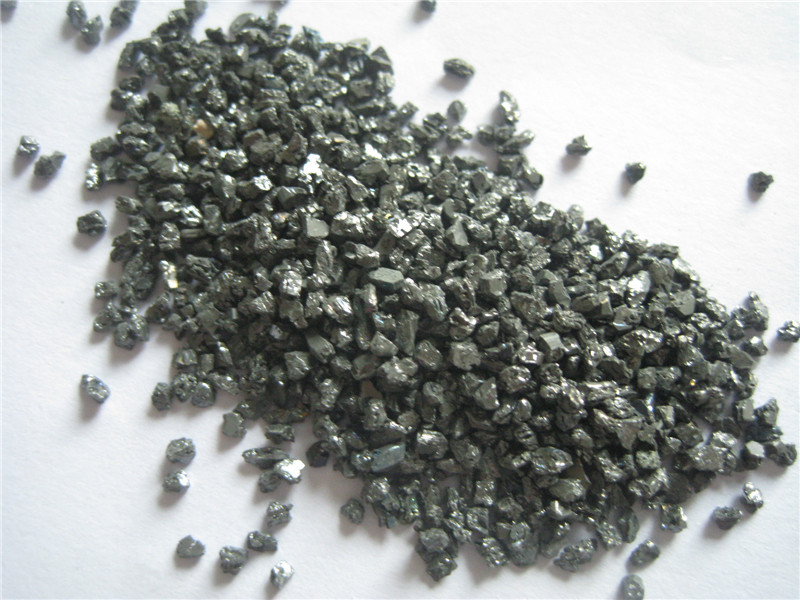

黑碳化矽典型化學分析 [%]

| 碳化矽 | 三氧化二鐵 | FC | F.Si | 二氧化矽 | 法律 |

| ≥98.5% | ≤0.40 | ≤0.20 | ≤0.40 | ≤0.70 | < 0.09 |

黑碳化矽物理特性

| 密度 | 3.20克/立方厘米 |

| 莫氏硬度 | 9.15 |

| 最高使用溫度 | 1900℃ |

| 熔點 | 2250℃ |

黑碳化矽粒徑分佈

| F008 | +4000um | 0 | +2800um | ≤20% | +2360um | ≥45% | +2360+2000um | ≥70% | -1700微米 | ≤3% |

| F010 | +3350um | 0 | +2360um | ≤20% | +2000um | ≥45% | +2000+1700um | ≥70% | -1400微米 | ≤3% |

| F012 | +2800um | 0 | +2000um | ≤20% | +1700um | ≥45% | +1700+1400um | ≥70% | -1180um | ≤3% |

| F014 | +2360um | 0 | +1700um | ≤20% | +1400um | ≥45% | +1400+1180um | ≥70% | -1000微米 | ≤3% |

| F016 | +2000um | 0 | +1400um | ≤20% | +1180um | ≥45% | +1180+1000um | ≥70% | -850微米 | ≤3% |

| F020 | +1700um | 0 | +1180um | ≤20% | +1000um | ≥45% | +1000+850um | ≥70% | -710微米 | ≤3% |

| F022 | +1400um | 0 | +1000um | ≤20% | +850um | ≥45% | +850+710um | ≥70% | -600微米 | ≤3% |

| F024 | +1180um | 0 | +850um | ≤25% | +710um | ≥45% | +710+600um | ≥65% | -500微米 | ≤3% |

| F030 | +1000um | 0 | +710um | ≤25% | +600um | ≥45% | +600+500um | ≥65% | -425微米 | ≤3% |

| F036 | +850um | 0 | +600um | ≤25% | +500um | ≥45% | +500+425um | ≥65% | -355微米 | ≤3% |

| F046 | +600um | 0 | +425微米 | ≤30% | +355微米 | ≥40% | 355+300um | ≥65% | -250微米 | ≤3% |

| F054 | +500um | 0 | +355微米 | ≤30% | +300微米 | ≥40% | +300+250um | ≥65% | -212微米 | ≤3% |

| F060 | +425微米 | 0 | +300微米 | ≤30% | +250微米 | ≥40% | 250+212微米 | ≥65% | -180um | ≤3% |

| F070 | +355微米 | 0 | +250微米 | ≤25% | +212微米 | ≥40% | +212+180um | ≥65% | -150微米 | ≤3% |

| F080 | +300微米 | 0 | +212微米 | ≤25% | +180微米 | ≥40% | +180+150um | ≥65% | -125微米 | ≤3% |

| F090 | +250微米 | 0 | +180微米 | ≤20% | +150微米 | ≥40% | +150+125um | ≥65% | -106微米 | ≤3% |

| F100 | +212微米 | 0 | +150微米 | ≤20% | +125微米 | ≥40% | +125+106um | ≥65% | -75微米 | ≤3% |

| F120 | +180微米 | 0 | +125微米 | ≤20% | ≥40% | ≥40% | +106+90um | ≥65% | -63微米 | ≤3% |

| F150 | +150微米 | 0 | +106微米 | ≤15% | +75微米 | ≥40% | +75+63um | ≥65% | -45微米 | ≤3% |

| F180 | +125微米 | 0 | +90um | ≤15% | +75微米 | * | +75+63um | ≥40% | -53微米 | * |

| F220 | +106微米 | 0 | +75微米 | ≤15% | +63微米 | * | +63+53um | ≥40% | -45微米 | * |

黑金剛砂第一章(JIS標準)

| 尺寸 | 溶氧(一) | D3(嗯) | D50(一) | D94(左右) |

| #240 | ≤127 | ≤103 | 57.0±3.0 | ≥40 |

| #280 | ≤112 | ≤87 | 48.0±3.0 | ≥33 |

| #320 | ≤98 | ≤74 | 40.0±2.5 | ≥27 |

| #360 | ≤86 | ≤66 | 35.0±2.0 | ≥23 |

| #400 | ≤75 | ≤58 | 30.0±2.0 | ≥20 |

| #500 | ≤63 | ≤50 | 25.0±2.0 | ≥16 |

| #600 | ≤53 | ≤41 | 20.0±1.5 | ≥13 |

| #700 | ≤45 | ≤37 | 17.0±1.5 | ≥11 |

| #800 | ≤38 | ≤31 | 14.0±1.0 | ≥9.0 |

| #1000 | ≤32 | ≤27 | 11.5±1.0 | ≥7.0 |

| #1200 | ≤27 | ≤23 | 9.5±0.8 | ≥5.5 |

| #1500 | ≤23 | ≤20 | 8.0±0.6 | ≥4.5 |

| #2000 | ≤19 | ≤17 | 6.7±0.6 | ≥4.0 |

| #2500 | ≤16 | ≤14 | 5.5±0.5 | ≥3.0 |

| #3000 | ≤13 | ≤11 | 4.0±0.5 | ≥2.0 |

| #4000 | ≤11 | ≤8.0 | 3.0±0.4 | ≥1.8 |

| #6000 | ≤8.0 | ≤5.0 | 2.0±0.4 | ≥0.8 |

| #8000 | ≤6.0 | ≤3.5 | 1.2±0.3 | ≥0.6 |

黑金剛砂第二章(FEPA標準)

| 尺寸 | D3(嗯) | D50(一) | D94(嗯) |

| F230 | <82 | 53.0±3.0 | >34 |

| F240 | <70 | 44.5±2.0 | >28 |

| F280 | <59 | 36.5±1.5 | >22 |

| F320 | <49 | 29.2±1.5 | >16.5 |

| F360 | <40 | 22.8±1.5 | >12 |

| F400 | <32 | 17.3±1.0 | >8 |

| F500 | <25 | 12.8±1.0 | >5 |

| F600 | <19 | 9.3±1.0 | >3 |

| F800 | <14 | 6.5±1.0 | >2 |

| F1000 | <10 | 4.5±0.8 | >1 |

| F1200 | <7 | 3.0±0.5 | >1(80% 時) |

| F1500 | <5 | 2.0±0.4 | >0.8(80% 時) |

| F2000 | <3.5 | 1.2±0.3 | >0.5(80% 時) |

黑金剛砂主要應用

- 固結磨俱及塗附磨俱

- 噴砂、表面處理、除鏽

- 濕式和乾式噴砂介質、研磨和拋光等

- 地板/牆壁層壓板,耐磨

- 陶瓷製品:陶瓷磚、陶瓷過濾板、陶瓷膜等

- 鐵氟龍塗裝等

- 隔熱材料

- 砂輪、杯形砂輪、油石、拋光墊等

- 用於坩堝、窯爐燃燒部件、機械密封件、半導體生產部件材料

包裝

25公斤PVC袋+1噸大袋

25公斤PVC袋+托盤

| 25公斤PVC袋 | 25KGS袋+1MT大袋 | 25KGS PVC袋+托盤 |